Offer

Provide additional details about the offer you're running.

Provide additional details about the offer you're running.

Provide additional details about the offer you're running.

What has a plane, a car, or a boat have in common with a surfboard? Well, for the last 50 years they haven’t had much in common, but now, technology used in aerospace, civil engineering, military, motorsports or water-sports has been transfer to Surfboards and we have developed a technology that is exclusive to Pukas. Want to learn more? Keep reading!

Traditional surfboards have been made of polyurethane (PU) foam covered with polyester resin. However, PU has an alternative to it that has come from other industries where lightness and toughness were key to performance of highly demanded environments. Now, the change that has irrupted the surfboard industry is the use of epoxy. An expanded polystyrene (EPS) core is covered with an epoxy resin. We are talking about a much harder material that is transferring its benefits to surfboards now.

That is exactly how you would feel: like your surfboard has come to life when it touched the water. It is a unique feeling that brings more liveness to the traditional surfboard construction.

If you look to an epoxy (EPS) constructed surfboard, you may think there is no visible differences to the traditional one (PU), but let us explain why this technology is and invisible one that will actually breathe life into the surfboard.

You may also think why start looking for new technology to apply to surfboards when there is also so much to study when it comes to designs and shapes, however that is another story. This one is about construction and how, by improving this key element of its process, can a surfboard be created and improved from that line of approach.

Epoxy material has a lightwave nature that along with the flex patterns that can be created using this resin system, puts an EPS surfboard in another “feeling” dimension, separate from the PU built surfboards.

And we can’t stop talking about that “feeling” of being alive transferred to the board under your feet. Why does this happen? How it feel like new? Due to some inherent qualities of epoxy resin, like its flexural memory using the epoxy resin with the 4oz. Using this system, the flexural memory is maintained a lot longer than a traditional board. This quality as well as its responsiveness, makes the board feel like new quite longer than a traditional one. The shiny new board feeling will be poping in time. Isn’t it dope?

We wanted to give one more step forward when it comes to using this new epoxy technology so we created the INN·CA Technology.

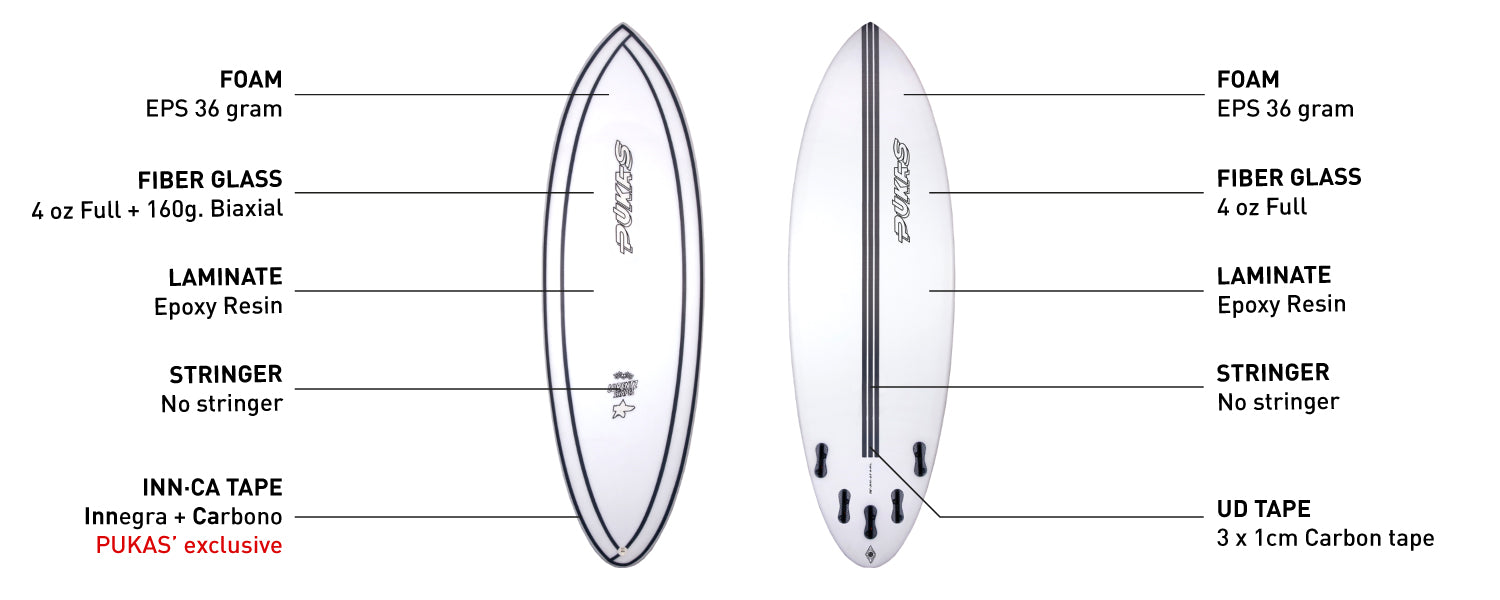

The INN·CA is a new epoxy surfboard technology that is exclusive to Pukas. Together, the white Innegra (INN) fiber and the black Carbon (CA) fiber, frame the rail of the surfboard and enhance the performance by damping high speed vibrations while increasing the fly characteristics of the EPS foam and Epoxy resin surfboards.

Shaped out of a stringer-less EPS foam, our exclusive Inner fiber is carefully marinated in bio base epoxy resin and cooked to perfection in a temperature that we keep secret.

Innegra fiber compliments other composite fibers lending itself to a variety of applications in a multiple of markets. Automotive, luggage, protective products, radomes, ballistics, and aerospace, to name a few, can benefit from the tough, lightweight, energy absorbing, long lasting and hydrophobic properties of this fiber.

INN·CA | Innegra · Carbon 70. High Performance enhancing frame.

Innegra material is used in many different sport and marine applications. Innegra fiber can enhance the impact resistance and damage tolerance while reducing weight and vibration.

The INN·CA Tape gives tensioning to the board, acting like if it was a stringer and the flex, depending on the design of the board, is even to maintain performance without renouncing to its light toughness.

Lightweitght 0.84g/cc |

Excelen Dielectrics |

Durable |

Low Elongation |

Minimizes Catastrophic Failure |

Highly Crystalline |

Ductible |

Hidrophobic |

Impact Resistant |

Energy Dissipation |

Vibration Damping |

Recyclable |

Our carbon fiber has several advantages including high stiffness, high tensile strength, low weight, high chemical resistance, high temperature tolerance allow thermal expansion. These properties have made carbon fiber very popular in aerospace, civil engineering, military, motorsports and water-sports. They are more expensive with similar fibers such as fiber glass or plastic fibers.

Mick Fanning holding the Pukas Dark during the Stab in the Dark IV. Pic courtesy of Cory Wilson.

The Pukas Dark was the runner-up choice for 3x World Champ Mick Fanning during the Stab in the Dark IV.

During this competition, the Pukas Dark was the fastest board reaching a top-speed of 38.4km/h. Pukas shaper Axel Lorentz wanted the board to be super fast: “I lowered the exit rocker and made the rails more parallel. The more parallel they are, the fastest the board goes.” Following this approach, Axel also acknowledged it would have a negative impact on maneuverability hadn’t he deepened the single concave; “deepening the concave in the Pukas Dark eases the maneuverability, which I also enhanced by adding a classic kick tail.”

Mick Fanning believes that a good board “has to perform well in all conditions”. During SITD Mick surfed Japanese typhoon condition, Californian Lower Trestles and his hometown Australian beach breaks that proved the Pukas Dark an internationally well-rounded high performance board he can trust.

This whole design is meant to be the highest-performance board in the Pukas portfolio. It begs a skilled surfer to perform on it, “you won’t find that ease of paddle because I have increased the rocker up in the nose and erased the extra foam in that area and putting it where a good surfer really needs it,” said Axel. It’s meant to fit in the most critical parts of the wave and help you connect fast with the next maneuver.

|

|